Product description

Extrea Tec is the highest quality screwed connection of rebars in the diameter range - 12-40 mm. This connection guarantees full load transfer for a given bar diameter. The basis of this system are specially upset bar ends, thanks to which weakening of the cross-section at the connection point is eliminated. Then, metric threads are made on ends. All threaded bars are connected using different types of sleeves.

Advantages of the Extrea Tec system

Production Extrea Tec

1. CUTTING

Bars are cut mechanically to size, perpendicular to the axis.

2. FORMING

Bars of the Extrea Tec system are upset at ends, which eliminates any weakening of the cross-section at the connection point.

3. THREADING

Metric threads are cut on ends.

A connecting sleeve is screwed onto the N type rods.

4. The final result is a ready connection.

The installation of bars for formwork.

Przy pomocy krążka montażowego: Przy pomocy listwy montażowej:

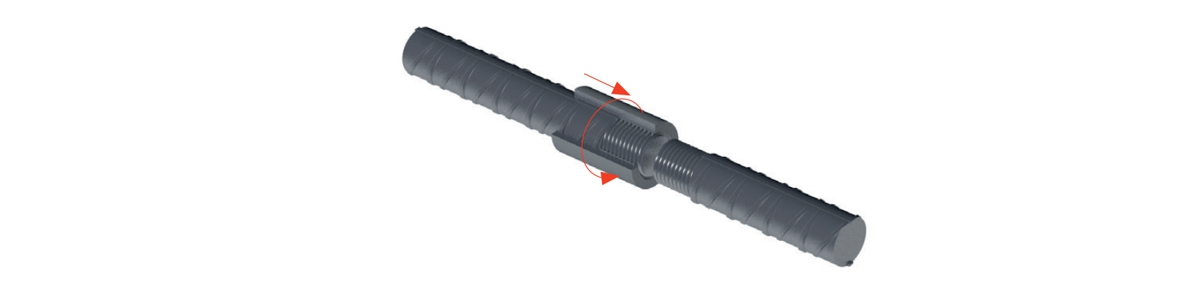

N type standard connection

This type of connection is used when it is possible to rotate the connected bar and move it along its axis.

1. The standard ES sleeve is screwed onto the base bar. The sleeve should be screwed on halfway (screw in until you feel resistance).

2. To the base bar with the sleeve, screw the bar with threading - B type.

3. The connection is ready

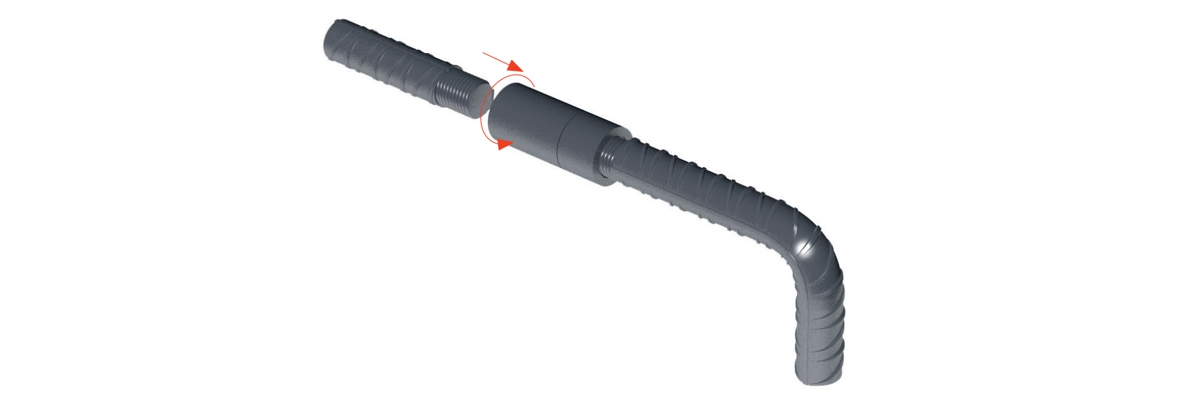

The NA type position connection

It is used when the connected bar is too long or it cannot be rotated.

1. At the end of the bar to be attached, prepare a special section of the thread that allows the standard sleeve to be screwed on until it is flush with the bar face.

2. Then we slide the bar connected to the base bar.

3. Then we slide the bar connected to the base bar.

The VB type position connection with the stabilization

We use it when the connected element cannot rotate and locking the bar position is required. This method is similar to the previous one, with the difference that here we additionally use a locknut, which stabilizes the position of the attached bar.

1. At the end of the bar to be attached, prepare a special section of the thread that allows the locknut of the standard sleeve to be screwed on until it is flush with the bar face.

2. Then we slide the bar connected to the base bar.

3. Screw in the sleeve until resistance is felt and stabilize it by tightening the locknut.

The distance connection

It enables smooth adjustment of the distance between ends of bars, which allows for the elimination of potential assembly inaccuracies. The maximum distance between bars may be one thread diameter.

1. At the end of the bar to be attached, prepare a special section of the thread that allows the locknut of the spacer to be screwed on until it is flush with the bar face.

2. Slide the connected bar to the base bar and screw the spacer to obtain the required position.

3. Stabilize the whole by tightening the locknut.

The reduction connection

This type of connection is used when it is possible to rotate the connected bar and move it along its axis, and connected bars differ in diameters.

1. At the end of the base bar, screw the reduction sleeve until it stops.

2. Then, screw in the connected rod until feeling a clear resistance.

3. The connection is ready.

The welded connection

This type of connection is used when we need to connect a rebar with a steel structure.

1. Weld a sleeve to the existing steel structure, remembering that the size of the weld should be equal to the depth of the welding groove on the sleeve.

2. Weld a sleeve to the existing steel structure, remembering that the size of the weld should be equal to the depth of the welding groove on the sleeve.

The screw anchoring

This type of anchoring is used when we need to connect a reinforced concrete structure or element with a steel structure or elements. The anchoring consists of a connected bar and a spacer into which the bolt is screwed (the bolt is not part of the system).

The anchoring in concrete

A connected bar is screwed into the small anchor plate (an EL version with a large anchor plate is also available). The other end of the bar connects to the rest of the reinforcement.