Compliant with current regulations and suitable for loads up to 22.5 N/mm2. Steel reinforced bearings for longitudinal sliding over enable effective bridge construction and movement of bridge structures. They provides controlled load transfer and allows horizontal movement with very low restraint and minimal rotation of the washer.

Supporting bridges and other similar structures

RUBA steel-reinforced elastomeric washers A, B and C types according to DIN EN 1337-3 (with CE mark).

1. Application

Steel-reinforced elastomeric washers from Extrea Polska have been a safe, reliable and maintenance-free elements supporting bridges and other similar structures for over 30 years. They bear high vertical loads and compensate for deflection as well as parallel displacements with poor restraint in the area of the washer.

2. The mode of action

The special structure of Extrea Polska reinforced elastomeric bearings ensures safe, reliable and maintenance-free transfer of high vertical loads generated by the self-weight and the working load of structural elements through the plastic-enclosed reinforcement plates. At the same time, deviations caused by e.g. deflections and parallel displacements caused e.g. by thermal changes due to deformation of high-class elastomer at a low level of restraint are compensated.

3. Properties

High-class steel plates are reinforcement arranged alternately with elastomer layers inside the washer – such a structure is particularly resistant to aging and weather conditions. Steel-reinforced washers from Extrea Polska are manufactured in the company's own production plant. The layered construction protects reinforcement plates against corrosion, thereby increasing the durability of washers. The use of various types of particularly high-quality chloroprene and natural rubber allows the use of washers at temperatures from -40 °C to +50 °C (for a short time up to + 70° C) and provides protection against environmental and weather conditions, especially against ozone and ultraviolet radiation.

4. The CE mark

It was necessary to successfully pass various tests to obtain a certificate confirming the production of reinforced elastomer washers in accordance with DIN EN 1337-3. These tests determined the following properties:

5. Compliance with the standard confirmed by external and internal quality control

5. Compliance with the standard confirmed by external and internal quality control RUBA reinforced elastomer washers are manufactured in accordance with DIN EN 1337-3. This standard was introduced by building supervisory organizations and is used throughout the EU. In accordance with the applicable regulations, our washers are subject to continuous externalquality control. At the same time, the quality assurance department takes care of the internal quality control of our products. After successful certification, our washers are CE marked according to EC certificate of conformity 0432-CPD-223286. This additionally confirms the compliance of the production with DIN EN 1337-3, in addition to other relevant documents.

Point 4, DIN EN 1337-1:2000:

"Washers should be designed to allow the expected displacements with the lowest possible responses."

We meet this requirement thanks to our own flexible production. High-quality RUBA steel reinforced elastomeric bearings are produced in accordance with DIN EN 1337-3 in any length and width ranging from 100 mm to 1000 mm and in the total height up to 400 mm. Roundshaped bearings in sizes up to 1000 mm are also possible. Extrea Polska's offer goes beyond standard assembly and includes washers with low reactive effects in accordance with the requirements of DIN EN 1337-1:2000 thanks to the use of special production facilities.

Flexible production also offers the following additional advantages:

F type unreinforced washers

We also manufacture non-reinforced RUBA F type washers in accordance with DIN EN 1337-3 with the same care and use of the same highclass materials .

Quality

Steel-reinforced elastomeric bearings from Extrea Polska have been a safe, reliable and maintenance-free element supporting bridges and other similar structures for over 30 years. This high quality is ensured by highly qualified specialists manufacturing RUBA reinforced elastomeric washers in accordance with DIN EN 1337-3 in modern production facilities. Permanent internal quality control carried out by the quality assurance department together with external quality control carried out by an independent research institute ensure a consistently high quality of production on which "you can build".

Types of washers according to DIN EN 1337-3 (the possibility of combining products)

RUBA A type reinforced elastomeric bearings are completely covered with elastomer and reinforced with one steel plate. These washers are used to compensate for deviations and parallel displacements under high vertical loads in a safe, reliable and maintenance-free manner. All reaction forces are transmitted through the elastomer to bearing surfaces.

![]()

RUBA B type reinforced elastomeric bearings are completely covered with elastomer and reinforced at least two steel plates. These washers are used when the deviations and parallel displacements are too great for the A type washers. All reaction forces are transmitted through the elastomer to bearing surfaces

RUBA B/C type reinforced elastomeric bearings are designed like B type washers, but with an additional steel plate of the cover flush with the surface of the washer. These washers are used when it is necessary to mechanically secure the washer against slipping. All reaction forces are transmitted via rubber-wrapped steel plates, e.g. by shear force protection, to the lower bearing surface and via the elastomer to the upper bearing surface.

RUBA C type reinforced elastomeric bearings are designed like B type washers, but with additional steel plates of shields flush with the surface of the washer. These washers are used when it is not possible to further transfer the thrust forces by the elastomer. All reaction forces are transmitted via rubber-wrapped steel plates, e.g. by shear force protection, to bearing surfaces.

RUBA C-PSP type reinforced elastomeric bearings are designed like C type washers, but with additional profiled steel plates of shields. These washers are used when it is not possible to further transfer the thrust forces by the elastomer. All reaction forces are transferred via rubber-wrapped profiled steel plates to bearing surfaces.

F type unreinforced elastomer bearings from Extrea consist entirely of elastomer. These washers are used to transfer deviations and parallel displacements under low vertical loads in a safe, reliable and maintenance-free manner. All reaction forces are transmitted through the elastomer to bearing surfaces.

![]()

Unanchored

- B type / A type

Contact surfaces should be smooth, horizontal, flat and free from dirt and oil. If necessary, differences in level should be smoothed out with the mortar. The mortar must meet the suitability requirements in accordance with DIN 1045. Side surfaces of the washer must be free and their possibility of deformation must not be limited by anything. B type bearings are usually placed on a smooth surface, reinforced with a layer of the mortar. At the top, the formwork should be placed close to side surfaces of the washer so that concrete cannot get between the washer behind the formwork. Open spaces between the contact surface and the formwork can be filled with polystyrene or similar material. The surface of the washer and the supported element should be in contact. There must be no films between them. Stacking two or more washers on top of each other is not allowed. Placing washers next to each other is allowed only if their stiffness is the same or only slightly different. The use of other types of washers is possible when only the same type of washers are used on single support footings.

Anchored washers

- C type anchored with pins

In the case of mounting bearings of anchored elastomeric washers already at the concreting stage, appropriate holes for pins and slots for their elements in the support footings should be prepared. After removing the formwork, prepare a smoothed contact surface at a suitable height. After curing, the washers are put in place and poured. On the upper side of the washer, the same steps are carried out as for the unanchored washer.

- C-PSP type anchored with profiled steel plates

of the shield

C-PSP type bearings should be mounted by placing profiled steel plates of the shield in the freshly applied mortar contact surface. The required height is set using wedges. After curing, wedges are removed.

Longitudinal sliding over and displacements of bridges

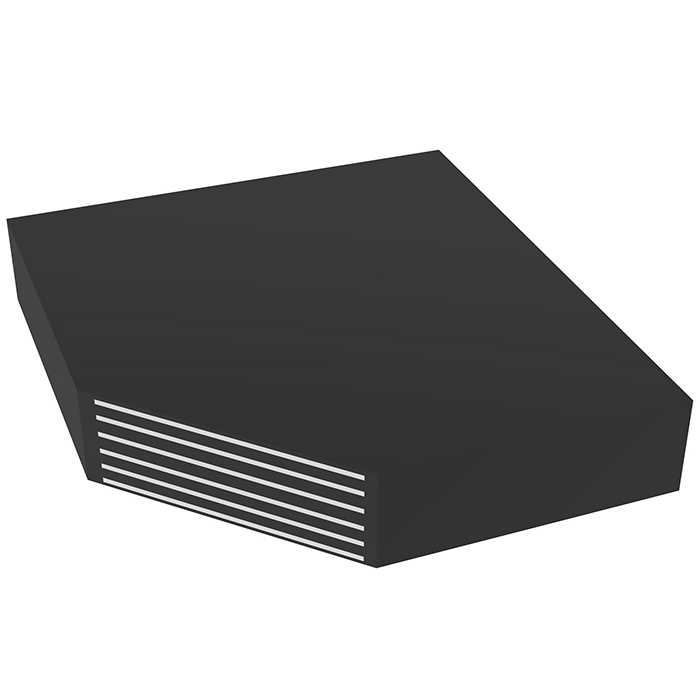

High load capacity steel-reinforced bearings for longitudinal sliding overBSL

Compliant with current regulations and suitable for loads up to 22.5 N/mm2.

Steel reinforced bearings for longitudinal sliding over enable effective bridge construction and movement of bridge structures. They provides controlled load transfer and allows horizontal movement with very low restraint and minimal rotation of the washer.

BSL steel-reinforced bearings for longitudinal sliding over are manufactured in standard thicknesses of 13, 18 and 25 mm. Other thicknesses are also possible. Washers consist of a high-quality special gray-coloured elastomer and steel reinforcement, as well as a PTFE layer with embossed lubrication gaps to improve long-lasting frictional properties. The gray elastomer has an advantage over the black elastomer in this case due to the colouring of the concrete.

The longitudinal sliding over method allows, in the case of long objects, to replace the traditional methods of erecting bridges and viaducts with the use of arch centres or spacing beams. It allows to optimally combine the advantages of concreting on site and the use of prefabricated modules. The term LONGITUDINAL SLIDING OVER defines a mechanized method of erecting large bridges. In the stationary formwork, behind the supports, the supporting structure is produced in individual work cycles. The individual elements are concreted one after the other and joined together by prestressing in a bendable manner. The centrally compressed bearing structure is displaced intermittently in the longitudinal direction by hydraulic presses. Specially developed BSL washers for longitudinal sliding over from RUBA are placed under the bearing structure, which slide on the corresponding slide slabs with low friction. Adequate lubrication with RUBA silicone grease of the BSL-SF type must be ensured. Edges of the stainless steel plate must be rounded. The slide of the bridge element must occur in a plane parallel to the washer.

| Type | Max. width | Max. length | Thickness | Max. load | Friction coefficient |

| mm | mm | mm | N/mm2 | ||

| BSL | 1000 | 1000 | 13 | to 22,5 (characteristic) |

Depending on the presence of grease, cleanliness, slide surface of the counterpart, surface load and temperature. The max. friction coefficient according to test certificate 852.0653-7 : γ = 0,009 |

| 18 | |||||

| 25 |

additives: RUBA silicon grease of the BSL-SF type

Specification: steel-reinforced washer for longitudinal sliding over of the BSL type for loads up to 22.5 N/mm2 dimensions ... x ... x ... mm, delivery and mounting on a smooth, flat and horizontal support surface. The surface must be clean and degreased. RUBA BSL type