General guidelines for the use of elastomeric washers and slide films

Only professional placement guarantees the proper operation of washers.

Failure to follow the instructions below may reduce the capacity of the washer.

Adjacent surfaces must be smooth, horizontal, even and parallel to each other.

Adjoining surfaces must be of adequate load capacity. The adequate transverse tensile strength must be ensured (see information on N15/N20 washers).Washers should be placed in the area of the static reinforcement placed in the concrete of adjacent (through the washer) elements of the structure.

The possibility of deformation of edges of washers (expansion during linear load, displacement, torsion) must not be blocked. When laying washers, both washers and contact surfaces must be dry. Do not stick washers with glue. If there is no anti-displacement protection, appropriate design measures must be taken. Washers must be free of grease, solvents and other similar substances, and in particular free of formwork release agent.

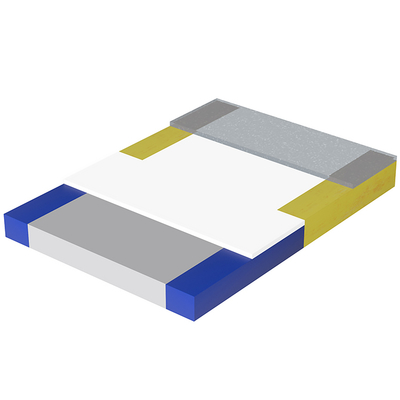

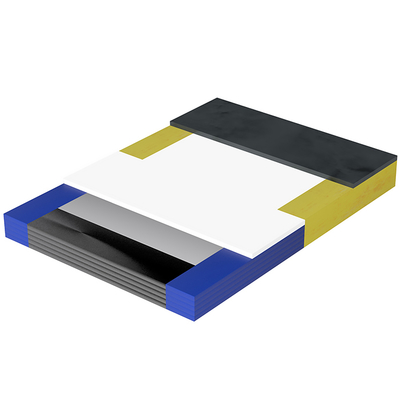

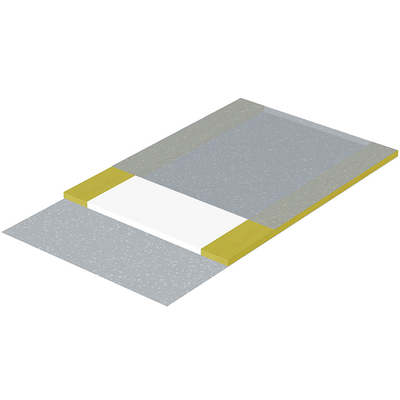

The arrangement for concreting on the site

The arrangement for concreting on the site

Usually, slide elastomeric washers are placed with the slide slab facing up (the whole surface is "hard"). Any separate designer's recommendations should be followed.

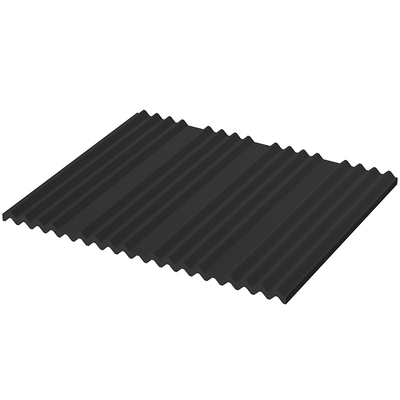

Additional instructions for SD ribbed washers

In the case of using prefabricated modules, the joint (slot) under the washer should be filled with a suitable soft material immediately after the washer has been installed.

In the case of on-site concreting, the surface of the SD ribbed washer should be protected with a rigid material (e.g. cardboard).

Only professional placement guarantees the proper operation of tapeslide washers.

Adjoining surfaces must be horizontal, even and free from dirt and oil.

For on-site concrete ceilings, place the formwork 15 mm to 20 mm above the top edge of the tape washer.

In the case of interior walls finished with plaster, leave a gap in the plaster at the level of the washer work.

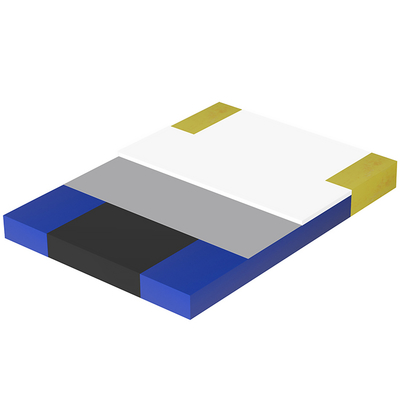

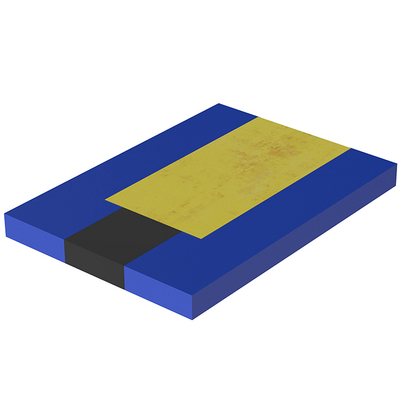

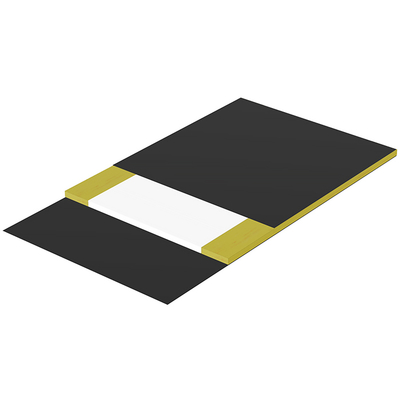

The assembly diagram

TG1A

When laying non-laminated slide films, contact surfaces must be very smooth, even and clean so as not to impair the functionality of the product. Otherwise, use protective layers to compensate for any unevenness of adjacent surfaces.

TG 1 A + b1, TG 1 A + b4 i TG 5 POM + b4

One-side laminated slide films should be laid with the laminated surface facing down.

TDG 27 SZ, TD 21 S

Core tape washers should be placed with the elastomer core facing down.

Ends of tape washers should be butt-jointed (without overlaps) and secured with adhesive tape to prevent concrete from penetrating.

NEVER FASTEN WITH NAILS!

Only professional installation guarantees the proper operation of the slide films used on large surfaces. Failure to follow these guidelines may cause the surface friction coefficient to deteriorate.

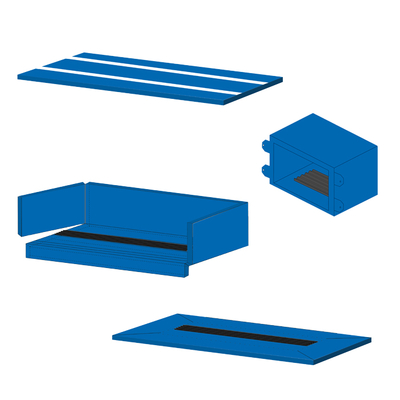

1. The substrate must be horizontal, level and smooth.

2. The bottom layer of nonwoven should be spread on the cleaned surface towards the longer side of the layer without the use of overlaps. Individual strips of nonwoven should be joined with adhesive tape.

3. First two strips of the sliding film should be placed perpendicular to the strips of nonwoven. Next strips of the film should be placed parallel to the first two strips.

4. The adhesive tape connecting long sides of the slide film must be removed. The first strip of foil (A) should be folded back to a width of approx. 20 cm and the next strip (B) should be inserted into the resulting gap (B) to a depth of approx. 5 cm, creating an overlap. After the foil strips are joined (overlapped), the overlaps should be covered with adhesive tape along the entire length of the joint. The same should be done in order to join subsequent strips of the slide foil.

5. The top layer of nonwoven should be laid without overlaps between strips in the same direction as strips of the bottom layer. Individual strips of nonwoven should be connected with the adhesive tape and protected against gusts of wind.